We are excited to announce an important operation: the conversion of filling stations currently fuelled by diesel into the new biofuel HVO (Hydrotreated Vegetable Oil) for the Autospedg Group, to which we had supplied Heconomy terminals with Hecpoll5 Saas in Cloud.

The Autospedg Group, controlled by the Gavio family through the Aurelia Srl holding company and active in the transport, logistics, vehicle construction, canning industry and major sporting events sectors, is making significant progress towards sustainability.

Aware as we are of how precious environmental resources are to everyone, we constantly seek to improve and innovate our solutions in order to create value and preserve the environment. The conversion of diesel to HVO (Hydrotreated Vegetable Oil), a sustainable biofuel, is a significant step forward for the Autospedg Group.

What are biofuels?

Biofuels are transport fuels produced from biogenic raw materials, such as plants, seeds or organic waste. These fuels are an alternative to traditional fossil fuels as they are renewable and can contribute to the reduction of greenhouse gas emissions.

There are several generations of biofuels, each with different characteristics and production sources. The first generation of biofuels was obtained from dedicated crops such as maize, rapeseed and soya. However, this production had negative implications for the environment, such as deforestation and competition with food production.

European legislation, for example, has moved towards the production of second-generation biofuels, which are produced from non-food feedstocks such as organic waste and biomass waste from agriculture, forestry and the food industry. These second-generation biofuels have a lower environmental impact than the first generation and can help reduce greenhouse gas emissions without compromising food security.

Biofuels can be produced from a variety of sources, including:

- Vegetable oils: oils derived from plants such as rapeseed, soybean, sunflower and palm.

- Biomass: organic material derived from plants and agricultural waste, such as straw, sugar cane and wood residues.

- Organic waste: organic waste from food or agricultural processes, such as waste cooking oil and fruit and vegetable scraps.

- Algae: algae can be used to produce biofuels, offering a sustainable alternative to traditional crops.

The production of biofuels requires transformation processes such as fermentation, oil extraction or chemical conversion. Biofuels can be used either as direct substitutes for fossil fuels or as blended components with traditional fuels.

The objective of biofuels is to provide a renewable and sustainable energy source for the transport sector, contributing to the reduction of greenhouse gas emissions and the transition to a low-carbon economy.

What is Hydrotreated Vegetable Oil?

HVO, which stands for Hydrotreated Vegetable Oil, is a type of biofuel produced through a process of hydrogenating vegetable oils. In this process, vegetable oils undergo a chemical reaction called hydrotreatment, in which they are treated with hydrogen at high temperature and pressure in the presence of a catalyst. This chemical reaction leads to the removal of oxygens and other impurities in vegetable oils, producing a high-quality diesel fuel.

HVO is an advanced and sustainable biofuel, as it is produced using renewable raw materials such as vegetable oils from crops that do not compete with the food chain, vegetable waste or agricultural processing residues. This differentiates it from other traditional biofuels such as biodiesel, which are mainly produced using edible vegetable oils such as rapeseed or soybean oil.

HVO has several advantageous features compared to conventional diesel, including a low sulphur content, a high cetane index (which improves combustion and reduces pollutant emissions) and good stability over time. Furthermore, it can be used without the need for significant modifications to existing diesel engines, as it is compatible with the technical specifications of fossil diesel.

The use of HVO as a biofuel contributes to the reduction of greenhouse gas emissions and air pollution, as it emits less CO2eq (carbon dioxide equivalent emissions) than fossil diesel. It is therefore considered a promising solution for the decarbonisation of the transport sector and the transition to more sustainable energy sources.

Eni, for example, produces HVO biofuels using Ecofining™ technology in its biorefineries in Venice and Gela. This technology enables the production of high-quality biofuels regardless of the feedstock, which can include vegetable oils, animal fats and used cooking oils.

How can TGI help you?

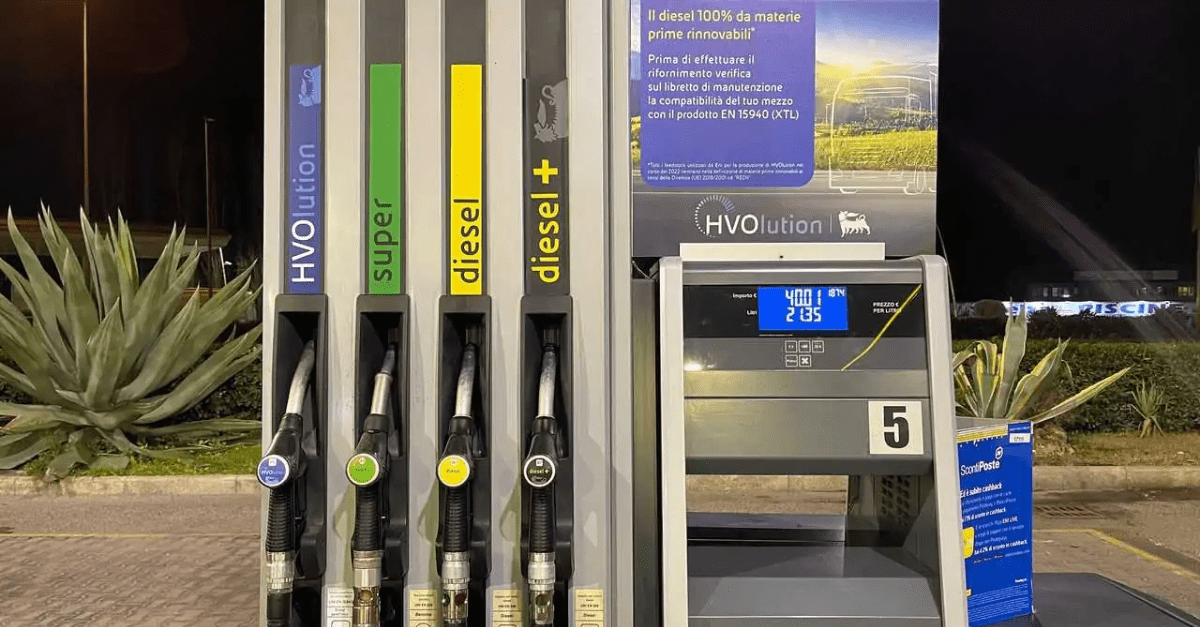

HVOlution is a biofuel consisting of 100% pure HVO. Before being marketed in Eni service stations, pure HVO was successfully used in several applications, including vehicles for handling people with reduced mobility at airports and commercial vehicles for logistics.

According to the criteria of Directive (EU) 2018/2001 “REDII”, the HVOlution has demonstrated a significant reduction of CO2 emissionseq along the entire logistics-production chain. In 2022, the emission reduction was estimated to be between 60 and 90 per cent compared to the fossil reference mix, corresponding to 94 g CO2eq/MJ. This contributes to the fight against climate change and the decarbonisation of the transport sector.

Here are some of the activities that TGI Tank Gauging Italia can carry out for companies interested in converting diesel into HVO:

Consulting and evaluation

TGI can provide technical advice and assessment of specific needs. This can include feasibility assessment, analysis of available options and support in selecting the most suitable solutions.

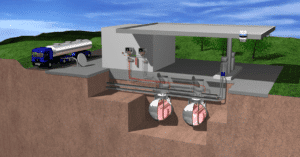

Installation and integration

TGI can manage the installation and integration of the required technologies at the company’s existing facilities or at new facilities. They can adapt and customise solutions to the customer’s specific needs, ensuring optimal integration with existing processes.

Technical and regulatory support

TGI can provide technical support in the use of HVO for the personnel involved and in managing the regulatory aspects and certifications required for the use of biofuels.

Monitoring and optimisation

TGI can offer performance monitoring and optimisation services to ensure that HVO production is efficient, sustainable and compliant with regulations. They can implement monitoring and control systems to assess plant performance and identify potential areas for improvement.

Choose TGI Tank Gauging Italia, the reliable partner to guide and facilitate the transition process towards a more sustainable energy source as Gruppo AutospedG did .