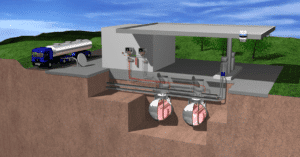

At Tank Gauging Italia, our primary focus is meeting the demands of our customers by providing reliable measurement and monitoring of tanks, analyzing and presenting related data, and ensuring flexible and seamless integration with desired host systems, all while maintaining the highest safety standards.

Thanks to our exclusive partnership with Hectronic and the marketing of carefully selected products, we are fully equipped to support our customers with utmost efficiency and reliability.

Why Hectronic? Because it’s the European tank content management leader company, providing best solutions for manufacturing probes, as well as user-friendly controllers and management softwares.

OptiLevel HLS 6010

Currently, the measurement data obtained from the OptiLevel HLS 6010 probe (link interno alla pagina sistema-controllo-giacenze-serbatoi), which accumulates on a daily basis, is primarily utilized to measure the fill level. This data is then displayed using the Mineo 2 Touch Controller.

The OptiLevel HLS 6010 probe, available in both wired and wireless versions, operates using Hectronic’s innovative floatless technology.

This technology eliminates the need for moving parts, resulting in a probe that is not susceptible to wear and tear, less prone to tank contamination, and boasts a longer service life with minimal maintenance costs. Furthermore, it ensures a unique and secure method of measurement.

One notable advantage of this system is its ability to not only measure the quantity of fuel in tanks but also determine its type and variations, including mixing and contamination. Statistical methods and Artificial Intelligence (AI) technologies enable this comprehensive analysis.

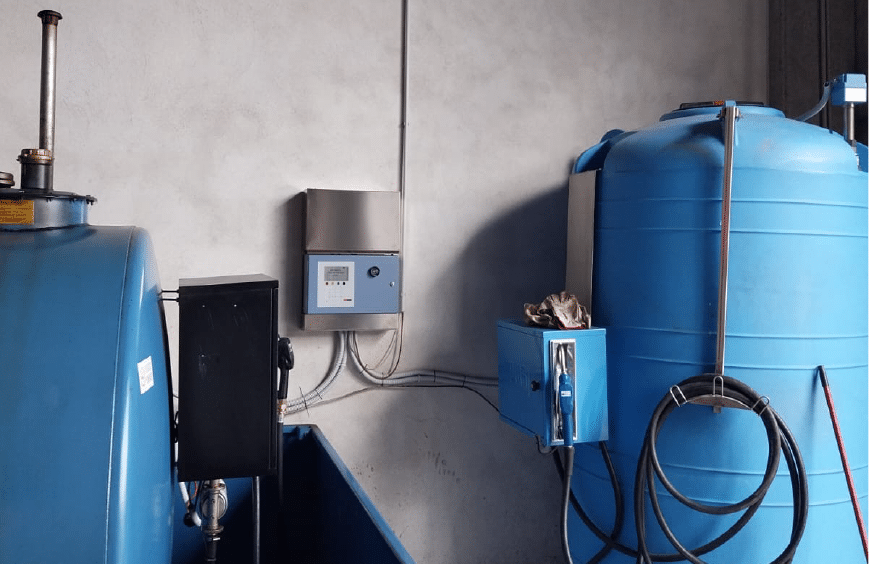

Mineo 2 Controller Touch and OptiLevel Connect

The Mineo 2 Controller Touch serves as a robust central hub for tank content management.

Featuring a user-friendly and intuitive interface, this powerful controller collects and stores all fill level data, which can be accessed online through Hectronic’s cloud service. Additionally, it supports monitoring of up to 32 tanks and enables the management of emergency alarms and data transfer to external devices from a single controller. It also provides various communication and connectivity options, facilitating seamless integration with third-party systems.

Not to be overlooked is OptiLevel Connect, a functional and user-friendly enclosure that serves as the interface between the upper-level system and the probes. It ensures galvanic isolation for each probe, offering reliable explosion protection.

Lastly, the Hecofill System, comprising a Level Controller (NK) and Hecofil Limit Probe, guarantees a high level of safety during the storage and transfer of hazardous liquids, regardless of their specific characteristics such as density, conductivity, and temperature. This system does not require calibration or special maintenance.