Double-walled tank conversion

Fenotec is the company specialized in the production of innovative anti-leak coating systems for underground tanks.

FENOTEC TANK COATING

Double wall creation and leakage control systems

TGI in cooperation with FENOTEC, a manufacturer and developer of the product, markets the innovative Fenotec tank coating for Italy.

We care about the environment and the safety of those around us. That is why we have partnered with Fenotec to bring their innovative lining to the Italian market. Our solution involves the patented installation of a fuel, oil, and hydrocarbon-resistant coating that provides long-lasting protection for underground tank units. This solution is suitable for situations where a tank leak has occurred, cases where a new alternative fuel needs to be loaded, or sites where there is a need to equip and monitor the tank with a double chamber, ensuring vacuum monitoring. We offer a solution that reduces costs and increases the long-term safety of your yard.

THE SOLUTION IN 5 STEPS

LEAK PROTECTION AND REMEDIATION

The first step in the installation process is to clean the tank, removing any residues from previous storage and potential metal abrasions that could damage or scratch the coating.

MEASUREMENT

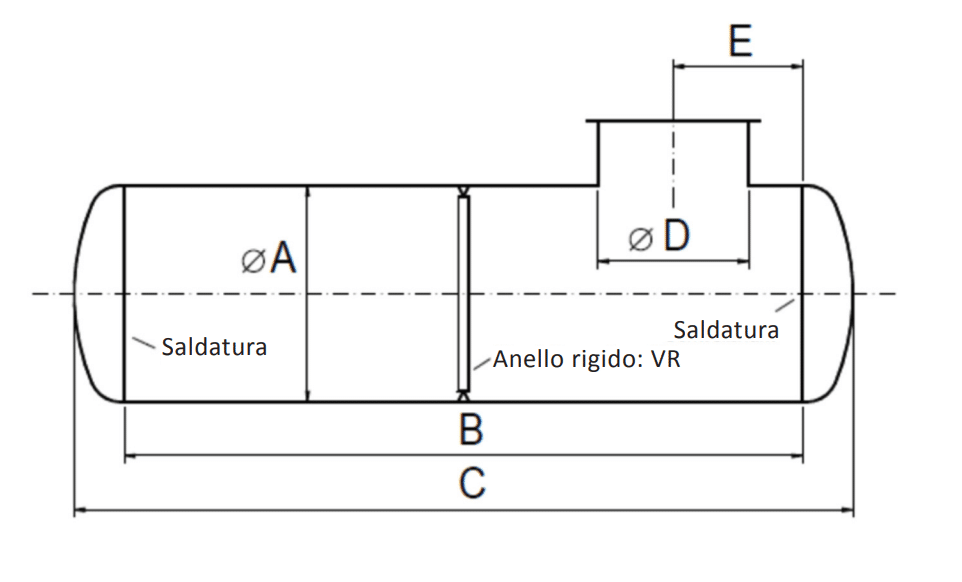

After the tank has been remediated, precise measurements are taken to customize the entire system.

KIT INSTALLATION

Once you have received the kit, it’s time to install it with our expert assistance, following straightforward guidelines. Throughout the installation, we provide comprehensive support and specific training, empowering you to become fully self-sufficient in this and future applications.

SYSTEM INFLATION

At this stage, the product needs to be inflated with air to ensure optimal adhesion to the tank walls. Once this is completed, simply connect the pre-assembled hoses to the included leak monitoring system.

COMMISIONING

Finally, you can proceed to fill the tank with the desired product.

Benefits

The System offers benefits such as:

- Safety.

- Elimination of chemicals harmful to the environment and the installer.

- Low costs.

- Shortened commissioning time.

- Possibility of future adjustment.

- Flexibility